0512-52977999

0512-52977999

gaojingmachinery@sina.com

gaojingmachinery@sina.com

0512-52977999

0512-52977999

gaojingmachinery@sina.com

gaojingmachinery@sina.com

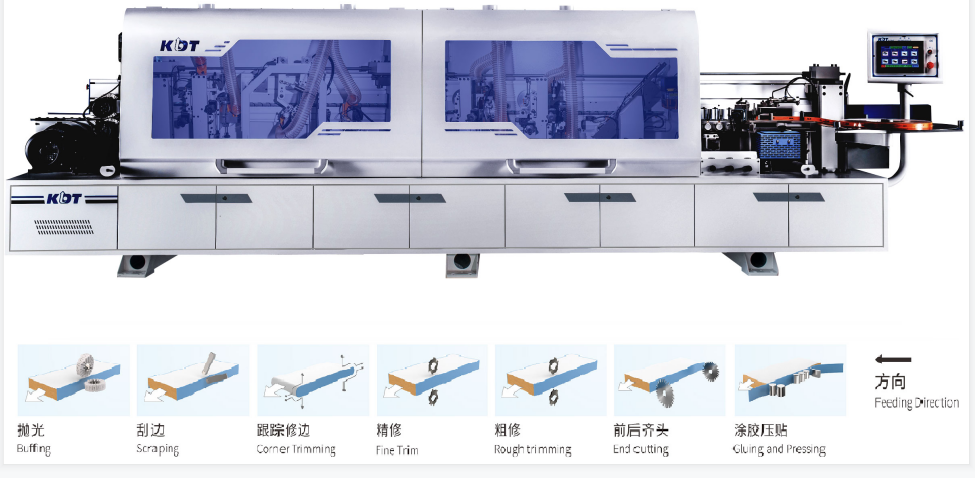

full automatic high speed edge banding machine Features:

, pre-milling + quick-up gluing 1+5 wheels pressing 1 + quick-up gluing 2+ 5 wheels pressing 2 + double rail end cutting + fine trimming 1 + fine trimming 2 + scraping 1+ scraping 2 + flat scraping + double running buffing 1+ double running buffing 2 + vertical hogging(equip with H model, horizontal hogging L is optional)

1. Function upgrade, satisfy the request of edging and hogging(hogging unit is optional)

2. Double fine trimming, improve the tool lifetime, using pneumatic control, can trimming with different kinds of radian.

3. Belt conveyor, the feeding speed is faster, improve the efficiency.

4. Heating lamp:heating when panel in, improve the pressing effect.

5. intelligent temperature control, can control machine glue temperature by touch screen setting, save electric power.

6. With 7.5KW conveyor motor;

7. Siemens electrical components

8. Heavy frame structure machine body.

9. Double up gluing( with pre-melt and auto adding glue)

full automatic high speed edge banding machine FEATURES

| ◆PC control: touch screen computer, HMI control, clear figure display, easy operating. Fault information can intuitively reflect the fault and troubleshooting through image and text display. |

| ◆Pre-milling mechanism, large diameter diamond cutter, motor power 3.7kW, maximum pre-milling height 40mm (optional 65mm), milling surface ripple and expansion material, edge bander effect is better. |

| ◆Double quick melt pressing mechanism, quick switch glue color into dark and light, more efficiency. |

| ◆5 wheels pressing unit, pressing more strong; with scraper on wheel, fix glue stock problem, easy for maintenance. |

| ◆Belt conveyor: | ||||

| ◆Heating lamp unit. heating when panels in , reduce the wasting rate and cost, improve the effect of edge banding | ||||

| ◆Auto gluing storage box:can reserve 13KG glue for auto adding. |

| ◆Double-rail end cutting unit, effectively cut off the edge tape from front to back, two saw blade works together, to achieve a best accuracy and efficiency. |

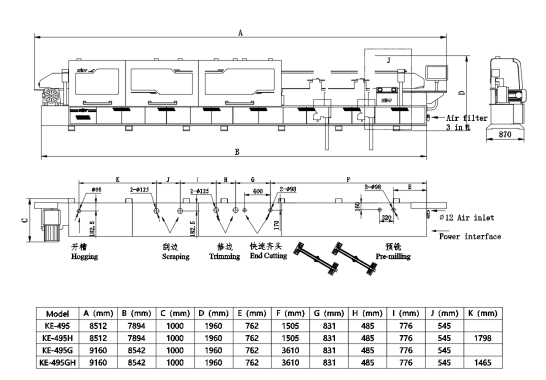

full automatic high speed edge banding machine LAYOUT DIMENSIONS

STANDARD MACHINE PARAMETERS | ||||||

STANDARD MODELS | PACKAGE SIZE(X Y Z) mm | GROSS WEIGHT(kg) | POWER(kW) | Working Pressure(MPa) | ||

KE-495 | 8612 | 1250 | 1960 | / | 25.62 | 0.6 |

KE-495G | 9260 | 1250 | 1960 | / | 30.75 | 0.6 |

KE-495GH | 9260 | 1250 | 1960 | / | 33.71 | 0.6 |